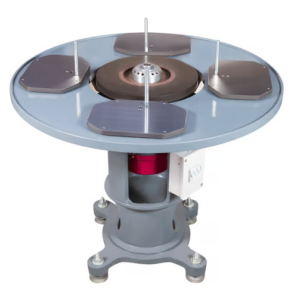

- Function: The primary function of this gauge is to translate linear movement into a clear, easy-to-read numerical value displayed on its dial face. It’s particularly important in manufacturing and quality control for determining accuracy and consistency. It can also be used to check various tolerances of manufactured parts, such as flatness, roundness, and runout.

- Measuring Range: This specific dial gauge measures from 0 to 20mm.

- Applications: These gauges are widely used to measure the thickness of various materials, including paper, pipes, sheet metal, leather, rubber, fabric, and plastics. They are also commonly used in the measurement of beads, jewelry, and pearls. In the field of mechanical engineering, they are crucial for production, fabrication, and quality control departments.

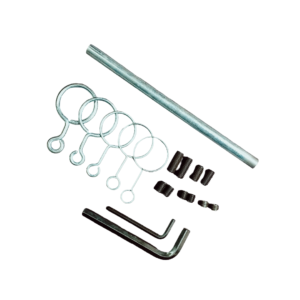

- Features:

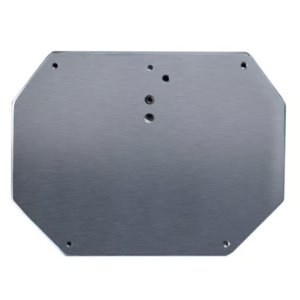

- It typically consists of a sturdy frame, a measuring anvil, a stem, a spindle (plunger), and a dial indicator.

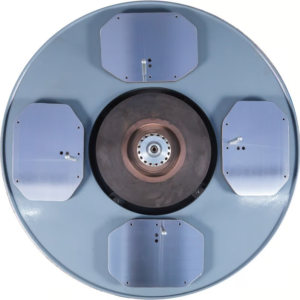

- The dial indicator displays the measurement on a calibrated scale with a needle or pointer.

- Some models may include a lock to fix the dial at a specific position, improving precision and ease of use.

- Contact points, which are crucial for accurate measurements, can be found in various shapes and are often made of hardened, wear-resistant materials like heat-treated steel, boron carbide, or diamond.

- A revolution counter (small dial) tracks the number of full rotations the main dial’s pointer makes, where each rotation typically signifies a 1 mm movement of the spindle.

- Operation: To use it, you place the material on the measuring anvil, adjust the gauge’s throat depth to ensure the spindle touches the material’s surface, secure the material if there’s a locking mechanism, and then read the measurement indicated on the dial.

In essence, the 0-20mm Dial Thickness Gauge shown in the image is a versatile and precise tool for measuring various dimensions and deviations, crucial in many industrial and scientific field

No products in the cart.

No products in the cart.

Reviews

There are no reviews yet.